- Test Bench

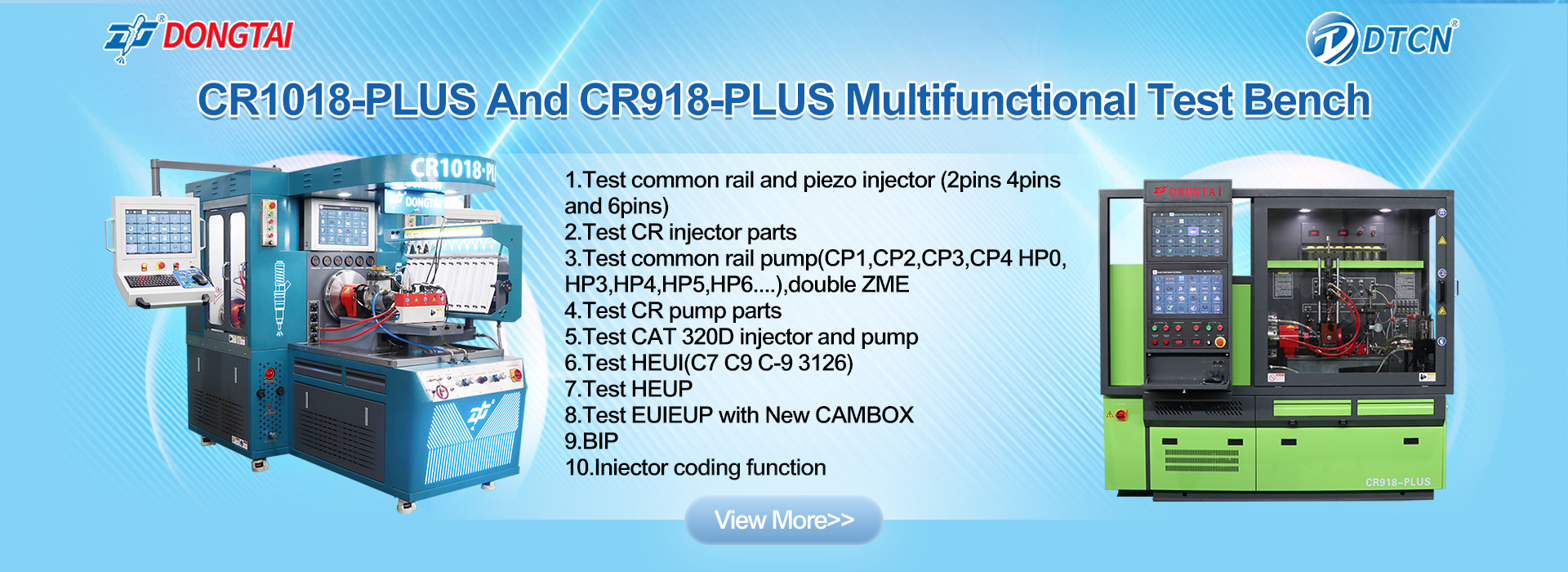

Diesel Injection Pump Test Bench Common Rail Injector Test Bench Common Rail Injector and Pump Test Bench EUI EUP,HEUI,CAT320D TEST BENCH Common Rail Simulator Nozzle Tester EDC Pump Tester/Sensor Tester CRI Stroke Measuring System PT Cummins Test Bench Balance Machine Work Bench Fuel System Tester DIAGNOSTIC SCANNER Stage3 Common Rail Injector Measuring Tools DPF,DOC,SCR Cleaning Machine

- Common Rail and EUI EUP HEUI HEUP Tools

- Diesel Engine Parts

Spare Parts Nozzle Plunger Head Rotor Delievery Valve Common Rail Shims Diesel Injector Tight Hat List 12V, 24V Solenoid Valve Bosch Pump Diesel Regulating Valve DRV Bosch Fuel Metering Valve DRV Bosch Fuel Rail Pressure Sensor Bosch Injector Valve Assembly Bosch Injector Valve Cap Pressure Limiting Valve Denso Valve Denso Valve Rod Denso SCV Valve Delphi Valve Delphi Rail Pressure Sensor Delphi Inlet Metering Valve CAT Plunger CAT Plunger Pump CAT Delievery Valve

- Bosch

- Denso

- Delphi

- CAT

- Cummins

- Siemens VDO

- Ultrasonic Tank Cleaner

- Wheel Loader

- Air Compressor

- AC Refrigerant Recovery Machin

PRODUCTS products

-

Free hotline

0086-13455388360

DPF-89H DPF , DOC, SCR Intelligent Automotive Aftereatment Regeneratiom Equipment

Content

FAQ:

1. What way for regeneration? Oil? Electricity? Water?

Answer: With 380V electricity, electricity is converted into high temperature heat energy of 0~800℃ for regeneration.

2. Why is the regeneration time so fast? What is the effect?

Answer: During regeneration, the heating is directly from the core part, without passing through the heat insulation layer from the outside to the

inside to heat, the core position reaches 700 ℃ within ten minutes, and the surface temperature of the exhaust pipe is only about 100 ℃ at this time,it is conceivable , when the outside of the exhaust pipe reaches 700 ° C, what is the internal temperature? Therefore, here can reduce the time for several hours, and automatically open the high-pressure purge mode while maintaining the temperature. During the regeneration process, carbon deposits, carbon ash, etc. have been Basically clean up. After the regeneration is completed, the equipment automatically turns on the rapid cooling mode, and the temperature drops to about 40 ° C within 5 minutes. The natural cooling time takes 2 hours or more; finally, the blast mode can be activated to completely remove the residue from the exhaust pipe. After testing and certification by authoritative institutions, the permeability after regeneration is as high as 96%, which is called perfect effect.

3. At present, the environmental protection of each region is strictly checked, does it meet the environmental protection standards?

Answer: The equipment is equipped with a thermal mutual anti-warm water cooler. The carbon deposited during regeneration and the carbon ash

emitted during gas explosion after regeneration will be sucked into the cooler. After filtration through water, all impurities will be collected, and just need to clean the filter element in time.

Add: High-Tech Zone, Taian, Shandong, China.

TEL:+86-13455388360 FAX: +86-538-2096189 E-mail: dongtai-china@hotmail.com

TAIAN DONGTAI MACHINE MANUFACTURING CO.,LTD 備案號:魯ICP備15006010號-1